Hallmarking process.

Customers must download and complete the Assay Docket in duplicate declaring the various precious metals/fineness and number of articles. The dockets must be submitted with the articles. Upon received of work parcels, the Assay Office commences the hallmarking process which consists of three steps:

1. Sampling

Our expert sampler withdraws samples from the articles for the purpose of chemical testing or selects a number of articles for non-destructive X-Ray fluorescence analysis for each work parcel.

2. Assaying (testing)

The fineness of the precious metal is confirmed either by chemical analysis or by non-destructive X-Ray Fluorescence Spectroscopy.

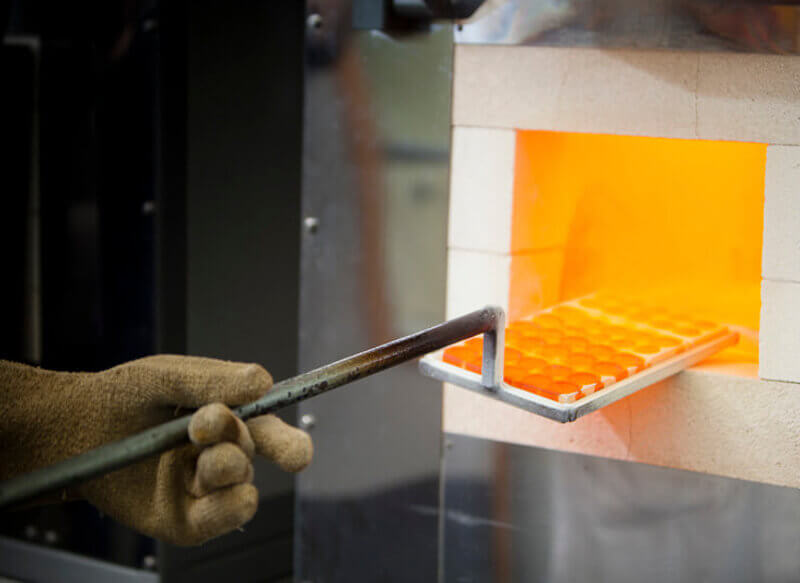

Gold is analysed by Cupellation (fire assay), a refining process to separate pure gold from the rest of metals in the alloy in order to calculate the gold content (normally expressed in parts per thousand).

Silver is analysed by potentiometric titration where a portion of alloy is dissolved in nitric acid and the resulting solution is titrated with potassium chloride solution to determine the silver content (normally expressed in parts per thousand).

3. Marking

There are three types of marking:

- Hand Marking – traditional struck hallmarking by punch or hammer.

- Press Marking – traditional fly press hallmarking.

- Laser Marking

A.Skeletal - outline laser mark. Can only be applied to finished articles.

B.Deep Laser - long lasting 3D laser mark which can withstand polishing.

Additional Information

If you require more information about the hallmarking process please don't hesitate to contact our office.